Electric Vespa Conversion

I converted a 1979 Vespa from gas to electric and partially solar using a commercially available conversion kit as the foundation of the drivetrain. The project focused on integrating modern electric systems into a legacy vehicle while replacing aging and unreliable components with updated mechanical and electrical solutions.

Scope of the Project

The conversion kit provided the core electric drivetrain components, but significant work was required to make the system function reliably on a nearly 50-year-old platform. Many original parts were worn, incompatible with modern electronics, or no longer safe to use as-is.

My role centered on system integration, solar installation, troubleshooting, and updating subsystems that the kit did not directly address.

Electrical and Systems Modernization

One of the main challenges was adapting the Vespa’s original electrical system to work with modern components. The stock wiring and circuitry were designed for a very different era and could not directly support updated lighting, switches, or safety features.

I replaced and rewired multiple circuits using modern wiring practices and components. In some cases, such as the brake light system, the original circuitry had to be fully rethought and rebuilt to accommodate modern lighting and switching behavior. This required tracing existing circuits, removing obsolete elements, and designing new wiring layouts that were safer and more reliable.

Additional Coverage

This project was featured in an interview and online newsletter discussing the conversion and modernization process.

Sewer Inspection and Sampling Rover

This project involved the design and construction of a robotic rover intended for sewer inspection and environmental monitoring. The goal was to create a compact, low-cost platform capable of remote operation and live video streaming in environments that are difficult to access using traditional sampling methods.

The project was completed as part of a multidisciplinary team involving mechanical engineering, physics, and environmental science students.

Problem

Urban runoff carries pollutants such as heavy metals and nitrogen into larger water systems. Existing monitoring methods are often limited by access and cannot easily reach deeper sections of sewer infrastructure affordably.

Our objective was to design a robotic platform that could operate remotely inside sewer systems, provide live visual feedback, and support future water sampling at multiple locations.

Mechanical Design and Packaging

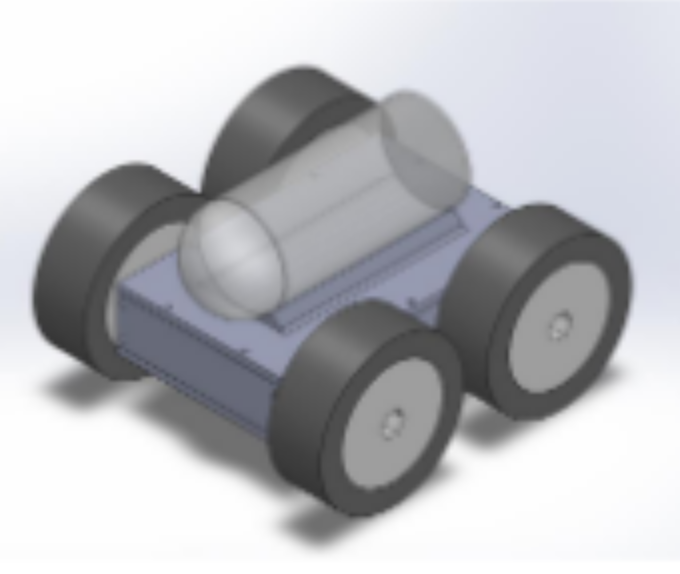

The mechanical design focused on creating a compact, serviceable chassis with sufficient internal space for electronics and future sensing hardware. Key considerations included protection of sensitive components, accessibility for maintenance, and integration of drivetrain and control systems within a limited volume.

I contributed to the mechanical layout and packaging of components, ensuring that electronics, motors, and structural elements could be assembled, accessed, and modified without major disassembly.

Electronics and Control System

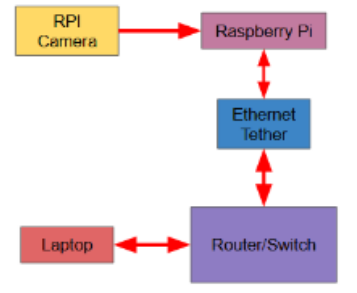

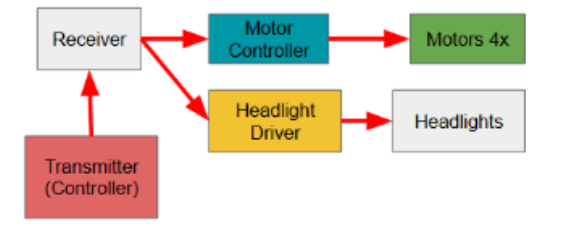

The rover used a multi-motor drivetrain controlled through electronic speed controllers and an RC transmitter and receiver system. A Raspberry Pi was used to provide a live camera feed, allowing the operator to remotely view conditions inside the sewer.

The camera stream was hosted locally, enabling real-time monitoring during testing. I worked on integrating the drivetrain electronics, control hardware, and camera system into a single, functional platform.

Prototyping and Testing

A working prototype was assembled and tested to verify drivetrain operation, control response, and live video streaming. Testing confirmed that the core systems functioned as intended and highlighted areas for future improvement related to environmental sealing and sensing capabilities.